Filter Technology

Our membrane filters consist of a bundle of hollow fiber membranes in a tube, where the space between the membranes and the tube has been hermetically sealed with an epoxy resin. This is a very efficient design with no unused space in the cartridge, as is the case in helically wound cartridges.

The low pressure drop across the membranes enables a very compact construction and high flow rates at point of use applications.

Filtration techniques

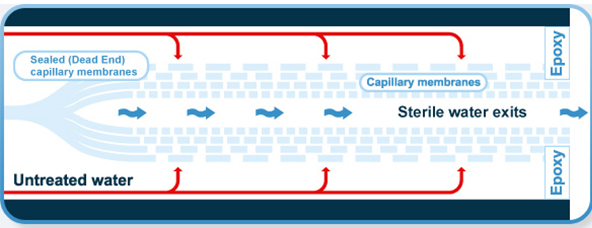

In the so called "Dead end" filtration technique (figure 1), the water flows from the outside to the inside and the filtered particles and bacteria (MF) or bacteria and virus (UF) are caught in the porous membrane wall, which gradually clogs. A decrease in flow rate to an unacceptable level is a signal for replacement of the filter. This technique is primarily applied with micro-filtration membranes in the Legionella Safe Shower filters, Inline filters and Dual Stage filters.

Dead-end filtration (fig.1)

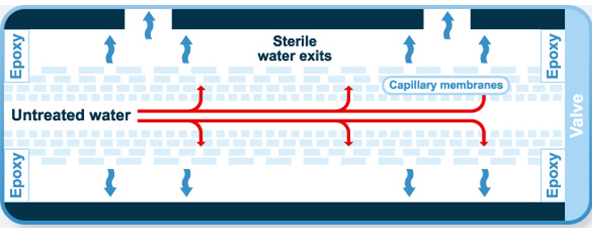

In the so called "Forward flush" technique (figure 2), the water flows from the inside to the outside, retaining the filtered particles, as well as virus (UF) and bacteria (MF and UF), on the inside of the membrane. This technique allows backwashing of the membranes from the outside to the inside with filtered water, while disposing of the dirt from the bottom of the cartridge.

Forward flush filtration (fig. 2)

Purification standards

Our membrane filters meet the highest purification standards. For example for filters with UF membranes the US EPA standard and protocol for microbiological water purifiers and for filters with MF membranes according to the ASTM F838 standard.

Service life

As a result of the broad and unpredictable variations in the nature and concentration of microparticles in the water, the service life of a "dead end" membrane filter will depend on local water conditions and the presence of pre-filtration. SDI (Silt Density Index) measurement or turbidity measurement can provide information on the service life of a "dead end" membrane filter.